Laser Descaling of Rolled Metal: Mechanisms, Operating Modes, and Comparison with Chemical Methods

Laser Descaling of Rolled Metal: Mechanisms, Operating Modes, and Comparison with Chemical Methods

Introduction

Descaling rolled metal is one of the key tasks in the metallurgical and mechanical engineering industries. Scale is a thin oxide layer that forms on the surface of metals during heating in the production process. It reduces coating adhesion, worsens the quality of welded joints, and accelerates corrosion.

Traditional cleaning methods include mechanical processing (brushes, grinding) and chemical treatment (acid baths, alkaline solutions). These methods have their limitations: mechanical cleaning can damage the metal, while chemical methods create environmental risks and require waste disposal.

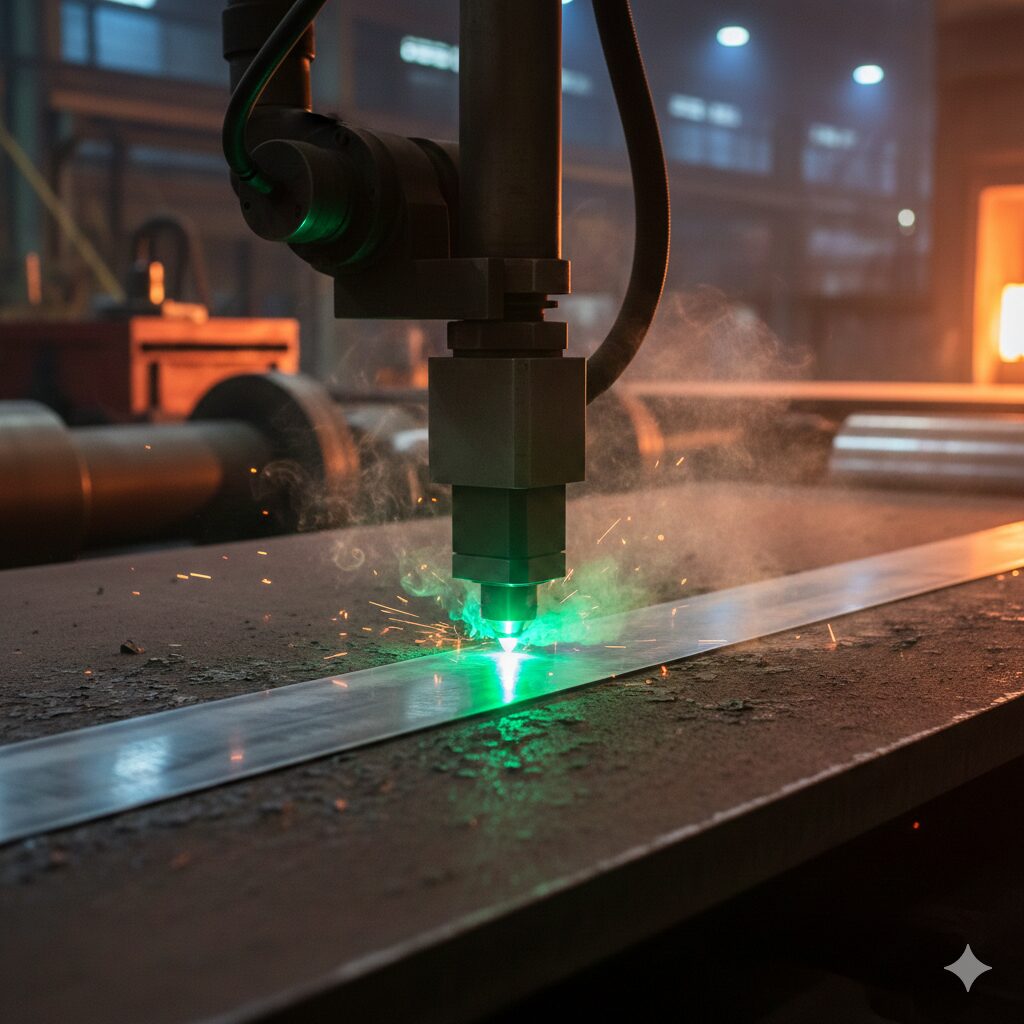

A modern solution is laser cleaning of rolled metal. This technology allows scale removal with high precision, minimal thermal impact, and without the use of aggressive chemicals.

Mechanisms of Laser Cleaning

Laser cleaning is based on the interaction of high-intensity laser radiation with the surface layer of scale. The main mechanisms are:

-

Ablation

A laser pulse vaporizes the scale, leaving the metal untouched. The efficiency of ablation depends on the laser wavelength and energy density.

Application: cleaning thin oxide films on steel and aluminum. -

Thermal Expansion

The difference in thermal expansion coefficients between the metal and the scale leads to scale detachment when heated by the laser.

Advantage: suitable for thick scale layers, minimal impact on the base metal. -

Plasma Interaction

At high power levels, localized plasma forms, which destroys the scale at the microscopic level.

Advantage: improves removal efficiency even on uneven surfaces.

The effectiveness of laser cleaning depends on the laser type (CO₂, fiber, diode), wavelength, power, pulse duration, and processing speed.

Laser Cleaning Operating Modes

To achieve optimal results, different laser operating modes are used:

| Mode | Features | Application |

|---|---|---|

| Pulsed | Short, high-intensity pulses; minimal heating of the metal | Micron-level cleaning, spot defects |

| Continuous (CW) | Constant radiation; high power | Thick scale layers, uniform coverage |

| Scanning | The laser spot moves across the surface | Cleaning large areas with minimal thermal impact |

Parameter Adjustment

-

Laser power: high power increases cleaning speed but may overheat the metal.

-

Pulse frequency: determines the uniformity of scale removal.

-

Scanning speed: too slow increases thermal impact, too fast reduces effectiveness.

The choice of mode depends on the type of metal, scale thickness, and surface quality requirements.

Comparison with Chemical Methods

Laser cleaning is often compared with acid and alkaline methods of scale removal. The main comparison criteria are:

| Parameter | Laser Cleaning | Chemical Treatment |

|---|---|---|

| Impact on metal | Minimal; metal retains its strength | Structural changes and corrosion possible |

| Environmental impact | High environmental safety; no chemical waste | Moderate; requires disposal of chemical solutions |

| Speed | High when automated | Moderate; often requires immersion and rinsing |

| Precision | Micron-level | Limited; difficult for localized treatment |

| Operating cost | High initial investment in laser equipment | Lower, but with chemical consumption and waste handling |

| Maintenance | Minimal after installation | Regular solution replacement and equipment cleaning |

Conclusion: laser cleaning outperforms in environmental safety, precision, and speed but requires higher initial investment.

Advantages and Limitations of Laser Cleaning

Advantages:

-

High precision and control over cleaning depth.

-

Possibility of automation and integration into production lines.

-

No chemical reagents and minimal waste.

-

Suitable for complex and sensitive surfaces.

Limitations:

-

High equipment cost.

-

Higher energy consumption compared to chemical methods.

-

Requires qualified personnel to adjust laser parameters.

Application Examples

-

Metallurgy: removal of scale from sheet metal before coating application.

-

Automotive industry: preparation of parts for welding and painting.

-

Electrical engineering: cleaning copper and aluminum surfaces for contact connections.

-

Equipment repair: removal of corrosion and oxide layers from turbines, machine tools, and presses.

Conclusion

Laser descaling of rolled metal is becoming the standard in modern industrial processes due to its precision, environmental safety, and automation capability. The correct choice of operating mode, power adjustment, and pulse frequency allows high efficiency without damaging the metal.

Comparison with chemical methods shows that laser cleaning is not only safer for the environment but also economically justified in large-scale industrial production. In the context of increasing quality and environmental requirements, laser cleaning of rolled metal represents an investment in long-term efficiency and reduced production risks.