10 Ways to Prolong the Life of Carbide Milling Cutters

10 Ways to Prolong the Life of Carbide Milling Cutters

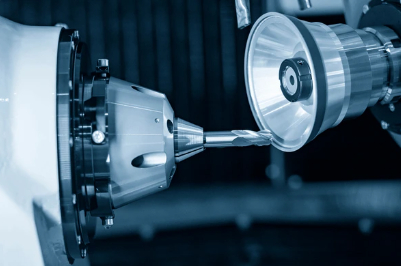

Carbide milling cutters are an essential tool in machining operations due to their durability, precision, and ability to cut through hard materials. However, even the best tools can wear out over time. Extending the lifespan of carbide end mills is essential for improving productivity, reducing downtime, and saving costs. Here are 10 expert tips to help you maximize the life of your carbide milling cutters.

1. Optimize Cutting Parameters

The key to extending tool life starts with optimizing cutting parameters, including cutting speed, feed rate, and depth of cut. High cutting speeds may increase productivity, but they can also lead to excessive heat buildup, resulting in faster wear. Experiment with slower feed rates and deeper cuts for better results, balancing performance and cutter longevity.

2. Use the Correct Tool for the Job

Always match the cutter geometry and material type with the task at hand. Using a cutter designed for specific materials or applications ensures more efficient cutting and reduces the risk of premature tool wear.

3. Keep Tools Sharp

Dull tools create more friction, generate excessive heat, and cause poor surface finishes. Regularly inspect your carbide milling cutters for wear and replace or sharpen them when necessary. A well-maintained tool performs better and lasts longer.

4. Control Coolant Flow

Proper coolant flow is crucial for both heat dissipation and chip removal. Inadequate cooling can lead to thermal cracking or premature wear on your tools. Use the right coolant, and ensure it is applied consistently and effectively during machining.

5. Avoid Overloading the Cutter

When the cutting load exceeds the tool’s capacity, it can lead to chipping, breakage, or excessive wear. Monitor the load during operations and avoid pushing the cutter beyond its recommended capacity.

6. Maintain Proper Tool Alignment

Misalignment can cause uneven wear on the tool, reducing its lifespan. Make sure your machine’s spindle, tool holder, and cutter are aligned correctly to prevent uneven force distribution and ensure smooth cutting action.

7. Monitor and Minimize Vibration

Vibration during cutting can cause tool deflection, poor finishes, and premature wear. To reduce vibration, make sure your machine is stable, and consider using anti-vibration tool holders. Additionally, ensure the workpiece is securely clamped to reduce movement.

8. Select the Right Material for the Workpiece

Different materials can be challenging for carbide cutters. Softer materials often create buildup on the cutting edge, while harder materials can cause premature wear. Make sure to choose the appropriate material type for the task and adjust your settings accordingly.

9. Inspect and Maintain Equipment Regularly

The longevity of your carbide milling cutters is directly related to the condition of your machinery. Regularly inspect the machine’s spindle, tool holder, and other key components to ensure they are functioning optimally. Well-maintained equipment reduces vibrations and ensures smoother cutting, prolonging the life of your tools.

10. Use Coated Carbide Tools

Carbide tools with specialized coatings, such as TiAlN or TiN, offer enhanced wear resistance, reduced friction, and better heat management. Coated carbide milling cutters are ideal for high-speed machining and heavy-duty applications, as they can significantly extend tool life.

Final Thoughts

Proper maintenance and usage of carbide milling cutters will not only help increase tool life but also improve your machining operations' overall efficiency. By following these 10 tips, you can save on costs, reduce downtime, and keep your machines running smoothly for longer. Always remember to choose the right tools, optimize parameters, and maintain your equipment for the best results.