How to Reduce Vibrations in High-Volume Milling

How to Reduce Vibrations in High-Volume Milling

Vibrations during milling are a common challenge in high-volume production. They negatively affect surface quality, tool life, machine components, and overall process stability. In serial manufacturing, even minor vibrations lead to significant losses.

Key Methods to Reduce Vibrations

Tool Selection

Use cutters with variable pitch and variable helix angles to suppress resonance. Keep tool overhang as short as possible and apply anti-vibration tools for demanding operations.

Cutting Parameters Optimization

Adjust spindle speed to avoid resonance zones. Small speed changes often stabilize the process. Balance axial and radial depth of cut to maintain constant tool load.

Rigid Workholding

Ensure secure and rigid clamping of the workpiece. For thin-walled parts, use adaptive or vacuum fixturing systems.

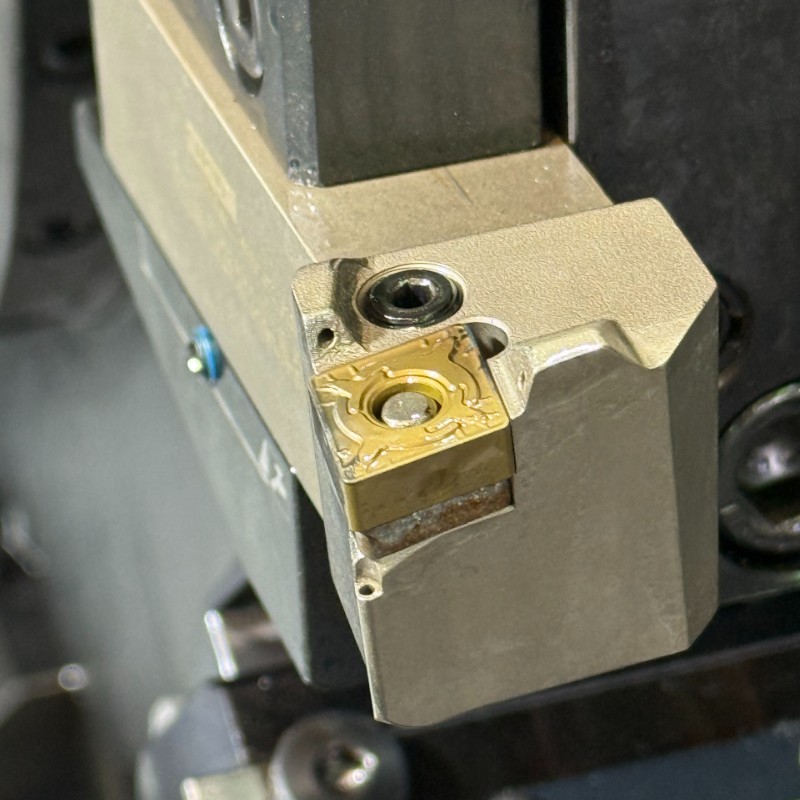

Balanced Toolholders

At high spindle speeds, toolholder balance is critical. Hydraulic or shrink-fit holders improve rigidity and reduce runout.

Tool Condition Monitoring

Worn tools increase cutting forces and vibrations. Implement controlled tool life management and spindle load monitoring.

CAM Strategies

Apply adaptive milling strategies with smooth toolpaths and constant engagement to minimize dynamic load changes.

Conclusion

Reducing vibrations in high-volume milling requires a systematic approach combining tooling, machine setup, cutting data, and software strategies. Proper optimization improves surface quality, extends tool life, and increases overall production efficiency.