Overview of New Materials for CNC Machining: From Composites to High-Strength Alloys

Overview of New Materials for CNC Machining: From Composites to High-Strength Alloys

Modern industries are actively adopting new materials that offer excellent strength-to-weight ratios, resistance to wear and corrosion, and improved performance under demanding conditions. However, machining these materials requires adjustments in tooling, cutting strategies, and cooling systems.

This article provides an overview of the most commonly used advanced materials, their benefits, machining challenges, and practical recommendations.

Carbon Fiber (CFRP)

Advantages:

-

High strength with low weight

-

Corrosion resistance

-

Excellent vibration damping

Challenges:

-

Abrasive wear of cutting tools

-

Risk of delamination

-

High sensitivity to vibrations

Recommendations:

-

Use diamond-coated tools (PCD)

-

Install dust extraction systems

-

Minimize cutting forces and vibrations

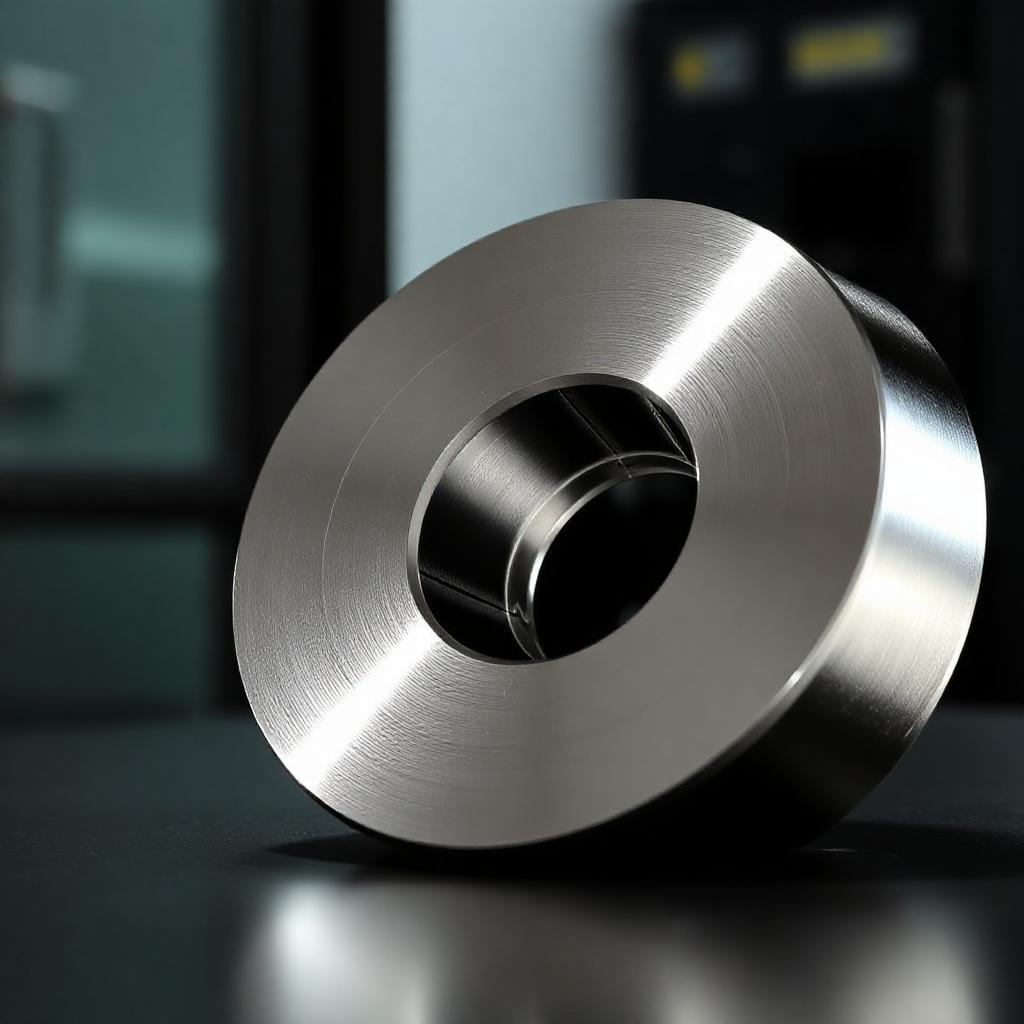

Titanium Alloy (e.g., Ti-6Al-4V)

Advantages:

-

High strength and corrosion resistance

-

Excellent strength-to-weight ratio

-

Biocompatible — widely used in medical and aerospace sectors

Challenges:

-

Poor thermal conductivity — overheating risk

-

Built-up edge on tools

-

Expensive material → high cost of errors

Recommendations:

-

Use carbide tools with TiAlN or AlCrN coating

-

Apply high-pressure coolant

-

Reduce feed rate, maintain moderate speed

Nickel Superalloys (Inconel, Hastelloy, Waspaloy)

Advantages:

-

Excellent high-temperature resistance

-

Outstanding corrosion protection

-

Dimensional stability under load

Challenges:

-

High cutting forces

-

Rapid tool wear

-

Tendency to work-harden

Recommendations:

-

Use wear-resistant carbide tools

-

Carefully monitor tool wear and cutting temperature

-

Use low depth and conservative cutting speeds

High-Strength Aluminum Alloys (7xxx series)

Advantages:

-

Lightweight with high mechanical strength

-

Good corrosion resistance

-

Common in aerospace and automotive industries

Challenges:

-

Chip buildup

-

Burr formation

Recommendations:

-

Use polished-flute cutters

-

Employ high spindle speeds, low axial forces

-

Prefer dry or MQL cooling

Engineering Plastics (PEEK, PTFE, Delrin)

Advantages:

-

Low weight and chemical resistance

-

Good electrical insulation

-

Easy to machine

Challenges:

-

Thermal deformation

-

Long, stringy chips

-

Low stiffness — prone to vibration

Recommendations:

-

Use sharp single-flute tools

-

Apply high spindle speed, low feed

-

Avoid overheating the material

Conclusion

Modern materials like composites, titanium, nickel alloys, and engineering plastics open new opportunities in design and manufacturing. However, successful CNC machining of these materials requires knowledge, preparation, and the right tooling.

UDBU can help you choose the optimal machining strategies, cutting tools, and equipment configurations.

Contact us today to improve your material processing efficiency.