English: Laser or Cold Saw for Pipe Cutting – What to Choose?

English: Laser or Cold Saw for Pipe Cutting – What to Choose?

When choosing pipe cutting equipment, many factors matter: precision, speed, cost, material type, and more. Let’s compare two popular methods — laser cutting and cold saw cutting — to help you decide which is right for you.

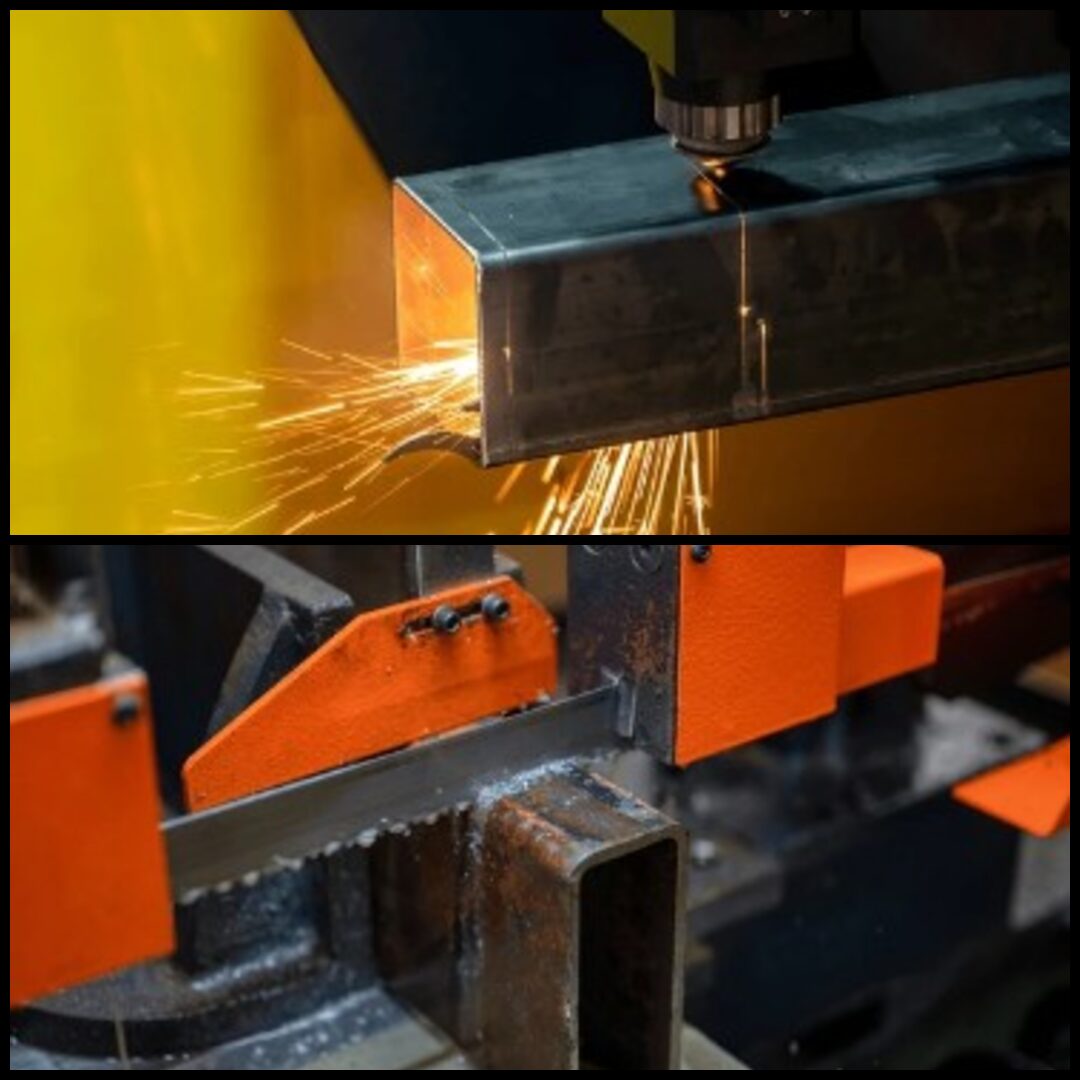

Laser Cutting

Advantages:

-

High precision and edge quality. Clean cuts with minimal burrs; often no post-processing required.

-

Flexibility. Ideal for cutting complex shapes, holes, and contours.

-

Automation-ready. Modern laser machines easily integrate into production lines.

Disadvantages:

-

Expensive equipment and maintenance.

-

Limited with thick pipes.

-

Requires skilled operator.

Best for: high-precision and small-batch production, cutting stainless steel, aluminum, copper, and other non-ferrous metals.

Cold Saw Cutting

Advantages:

-

Affordable. Lower equipment and maintenance costs.

-

Efficient with thick-walled pipes.

-

Easy to operate and maintain.

Disadvantages:

-

Limited to straight cuts.

-

Less precision. May require additional finishing.

-

More noise and material waste.

Best for: mass production, cutting ferrous metals, straightforward operations with large-diameter pipes.

Summary Table:

| Factor | Laser Cutting | Cold Saw Cutting |

|---|---|---|

| Precision | Very high | Medium |

| Speed | Moderate | High (on straight cuts) |

| Equipment Cost | High | Medium/Low |

| Complex Shapes | Yes | No |

| Maintenance | Complex/Expensive | Simple |

Conclusion

If precision and versatility are top priorities, go with laser cutting. If you need cost-effective, high-speed cutting for standard operations, cold saw is your choice.

Need help choosing equipment? Contact our team — we’ll help you find the best solution for your project.